Technical Information

European Technical Approval

The PFSolutions System achieved European Technical Approval from the European Organisation for Technical Approvals (EOTA) in July 2007. The British Board of Agrement (BBA) is the UK representative for the EOTA and is responsible for issuing European Technical Approvals in the UK. The PFSolutions System has therefore achieved the equivalent of BBA certification and achieved the required ‘CE’ mark of approval.

A full copy of the European Technical Approval is available upon request.

| Fire Resistance | ||

|---|---|---|

| Wall thickness (including CBPBs) | Verification procedure | Fire resistance period (min) |

| 150mm | ETAG 009, Annex C |

REI 30 |

| 175mm | REI 90 | |

| 200mm | REI 120 | |

| 215mm | REI 120 | |

| 230mm | REI 120 | |

| 250mm | REI 120 | |

| 300mm | REI 120 | |

| Acoustic (Airborne sound insulation) | ||

|---|---|---|

| Wall thickness (including CBPBs) | Verification procedure | Acoustic rating |

| 150mm | EN ISO 140-3 EN 12354 and ENISO 717-1 |

Rw = 51dB |

| 175mm | Rw = 53dB | |

| 200mm | Rw = 55dB | |

| 215mm | Rw = 56dB | |

| 230mm | Rw = 57dB | |

| 250mm | Rw = 58dB | |

| 300mm | Rw = 61dB | |

| Thermal resistance | ||

|---|---|---|

| Wall thickness (including CBPBs) | Verification procedure | Thermal resistance |

| 150mm | Calculation according to EN ISO 6946 |

R = 0.229m2K/W |

| 175mm | R = 0.240m2K/W | |

| 200mm | R = 0.251m2K/W | |

| 215mm | R = 0.257m2K/W | |

| 230mm | R = 0.264m2K/W | |

| 250mm | R = 0.272m2K/W | |

| 300mm | R = 0.294m2K/W | |

Thermal CO2

The energy expenditure required (embodied CO2 burden) to produce a concrete structure is greater than for steel or timber structures. This embodied CO2 burden can be demonstrated, subject to BREEAM (BRE Environmental Assessment Method), to be offset against the operational CO2 emissions, many times over, in comparison to lighter-weight forms of construction employing active heating and/or cooling systems which are not based around the structure’s inherent thermal mass.

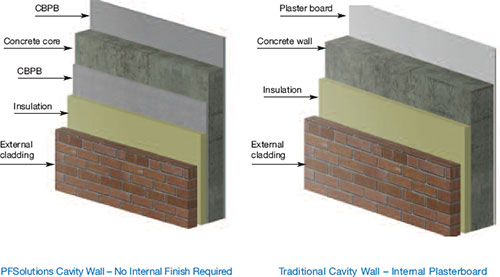

Plasterboard on walls and ceilings acts to reduce the effectiveness of heavyweight thermal mass benefits as it is more (heat) reflective than exposed concrete or masonry.

The thermal conductivity (λ) of Cetris board (24mm thick) is 0.26W/mK in comparison to plasterboard which is 0.17W/mK. There is no cavity in the PFSolutions system between the permanent-form panel and the concrete as there is with conventional plasterboard panels which have been dabbed onto the wall. The absence of this cavity further improves the thermal mass rating of the PFSolutions system.